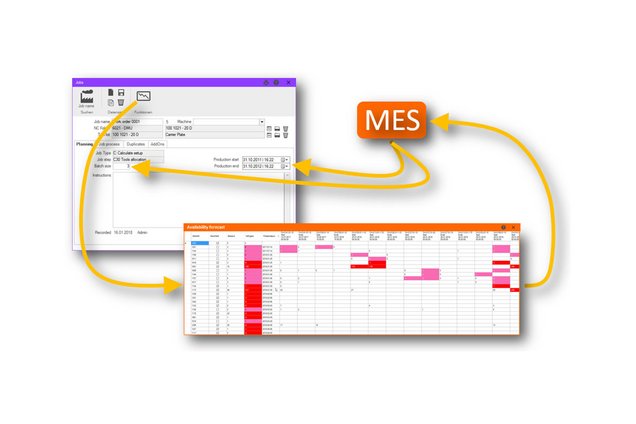

Industry solution

One of the typical WinTool solutions for the Job Shop industry

The total transparency of resources at the moment of planning!

The data from the MES or other planning systems are automatically transferred to WinTool. NC folders are automatically created and all data such as machines, part numbers, production start and end, as well as the lot size are transferred. You can see already during the order planning which resources are missing. Returned material such as consumables which is not available in sufficient quantity for the planned start of production are clearly listed. In this way, you can optimally schedule the order at any time, and order the tools you need during the planning Process.

The Task

- Transparency of return materials such as consumables at the time of order scheduling

- Availability preview of all tools and equipment required for production orders from the start of production to the end of production

- Automatic creation, transfer and synchronization of all necessary digital production data & information from the MES or order planning system

Your Benefit

- No more missing / disregarded workbooks and jobs, or erroneous information related to production data

- Ordering of consumables at the earliest possible time

- Optimal order planning for returned materials

- No more machine downtime due to missing tools and Equipment